What can be made from a mattress. Simple sleeping bed with your own hands.

Foam rubber is a filler that is made in various ways, so manufacturers today have the opportunity to offer options for products made from it for every taste. Porolo new mattress you can choose hard or soft, more or less elastic, regular or orthopedic.

How to choose a quality mattress

In order for the purchase to provide complete rest for many years, it is necessary to choose a mattress with high-quality filling. The foam inside must be tight, it depends on what loads it can withstand. There is a special stiffness factor, but you can check it and in a simple way - to see how quickly the foam rubber straightens after deformation, whether it cracks when pressed and stretched. The density of the filler is essential to ensure that the spine has the necessary support during sleep and that the body's weight is distributed correctly.

When buying, preference should be given to well-known manufacturers with a good reputation, then the foam mattress will serve for a long time and effectively.

Advantages of a foam mattress

Mattresses made of foam rubber have a lot of positive characteristics:

The production of this filler is economical, so it is worth buying a cheap foam rubber mattress if you need to buy a thing for little money that is not inferior in quality to more expensive models.

Making a foam mattress with your own hands

You should not rush to a furniture store in order to purchase such a leisure accessory. The manufacturing technology of this item is so simple that it will not be difficult to make a foam mattress with your own hands.

To do this, you will need: foam rubber, fabric for a cover, a sewing machine, scissors, threads, needles.

First, the marking of the mattress is made on a piece of foam rubber. Then, accordingly, a pattern is made on the fabric intended for the cover, while a few centimeters must be left for allowances and seams. This mattress cover is sewn on sewing machine and put on the prepared foam rubber. For more convenient use, it is recommended to sew a zipper into it.

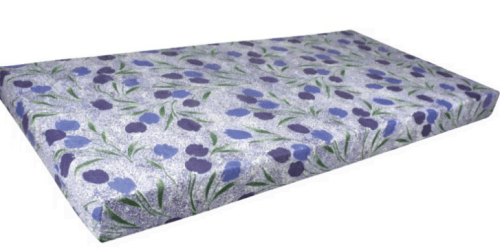

The main role of the cover is to protect the filler from external influences (dirt, rubbing, moisture). But, in order to give the mattress a more respectable and aesthetic look, the fabric of the cover should not only wash well, but also have a pleasant texture and beautiful colors.

Which mattress is better - cotton or foam

Both cotton and foam rubber products are approximately in the same price category. They also have many similar positive qualities - lightness, compactness, ease of transportation. A significant difference is the fact that there is a possibility of the appearance of all kinds of microorganisms and mites. It is unsafe for health, especially for people prone to allergies. Over time, the foam mattress may deform, and the cotton filler usually shrinks into lumps.

In military units, medical and children's institutions, preference is given mainly to mattresses with foam rubber filling, since it is the safest for health and easy to clean. Thanks to these properties, it is also recommended to use such accessories for strollers.

In order for the filling in the mattress to be distributed correctly, the first 3-4 months it should be turned over every 2 weeks. Then this can be done once every 3 months.

Ventilate the mattress monthly by leaving it in the air for at least 5 hours. Cleaning is easy with a conventional vacuum cleaner. If there are any small stains, a sponge soaked in any upholstery cleaner or soap solution will help. If the contamination is serious enough, then dry cleaning will be required when using special cleaning agents for such materials. If water gets on the mattress, wipe it with a dry cloth and dry thoroughly. Only then can it be covered with bedding.

Foam rubber absorbs odors very well. This should be taken into account when carrying out repairs, disinfection and other measures involving the use of strong-smelling agents. In such cases, it is better to wrap the surface of the mattress with a cover that does not allow air to pass through.

You will need

- - foam rubber;

- - synthetic winterizer, batting or other stuffing;

- - fabric for the cover;

- - sewing machine;

- - threads;

- - spring blocks;

- - wooden slats;

- - cord;

- - nails;

- - hammer;

- - stapler.

Instructions

Before you start doing mattress by their hands, determine what will be inside. If you need removable mattress, which can be folded and removed after use, choose a foam or synthetic winterizer base, and for a stationary bed, you can also make a spring mattress.

To make foam mattress, buy a piece of foam and mark out the shape. There may be several options here. If you need foldable mattress, make it from several parts, placing them across the bed. For a stationary bed, carve out a large mattress from one or two longitudinal parts. Cut the foam rubber together with an assistant, one of you should stretch the halves, and the other with a sharp knife cut exactly along the marked line.

Mark the pattern on the fabric, adding a thickness allowance on each side mattressand a few centimeters at the seams. To make the cover washable, make it like a pillowcase - with an overlap. To do this, add another 20 cm along the length.

Sew the cover for mattressa, first all the cross sections, then along the length, laying the corners across the side seams along such a width, what is the width of the foam rubber. Overlock or zigzag all seams. Slide the foam into the cover.

To do mattress from batting, padding polyester or other soft stuffing, start with a cover. Measure the size of the bed, consider the thickness when creating a pattern mattressand. Then sew a cloth cover of the required size, with an overlap or a zipper. Fill it carefully with padding, considering that it will nail down pretty quickly and become twice as thin. To prevent the stuffing from getting lost in a lump, sew in several places mattress through, attaching small pieces of fabric on both sides.

If you want to make a spring mattress, you need to buy spring blocks, their number depends on the size of the bed. Arrange them in order, strictly vertically, make sure that the upper ends are at the same level. Fasten the lower parts of the springs with wooden slats 2 cm thick and 6-7 cm wide.

Wire the springs. To do this, drive large nails (50-60 mm) into the ends of the bed opposite each row and bend them away from the springs. Take a strong cord 2-5 mm thick and tie all the springs of each row, first across the bed, then along and last along two diagonals. Place a burlap or other thick fabric, then a layer of batting or padding polyester, cover mattress upholstery fabric, securing it with a furniture stapler.

To make their car look more attractive, many car owners buy additional equipment for it. One of them spoiler... But there is an opportunity to do it on your own.

You will need

- - one sheet of foam plastic 1x1 m, 5 cm thick

- - 2 running meters of fiberglass

- - sheet steel 1.5 mm thick and welded

- - three cans of paint

- - two cans of primer

- - 2 kg epoxy adhesive with hardener

- - coarse sandpaper and very fine sandpaper

Instructions

Cut out the speaker details from plywood. We sand the surfaces, removing the burrs. We connect the parts with self-tapping screws. We glue the joints with wood glue. We pay special attention to tightness - this is reflected in the sound quality.

We process the surface of the speakers with paint or glue it over with various films that imitate various surfaces - metal, stone, wood.

We fasten the speakers to the speaker case. We hide the free wire inside the column.

Related Videos

note

Sources:

- Forum of mobile phone owners describing the process of making homemade speakers.

A full-fledged role-playing game implies that the role-playing player has a variety of gaming accessories and paraphernalia corresponding to his role, as well as the era that he is playing. If you are playing a magician in an RPG, you need an appropriate setting. In addition to a cloak and a staff, you will need a magical scroll... To make such scroll you can at home.

You will need

- - scissors,

- - PVA glue,

- - long ruler,

- - a simple pencil,

- - two cardboard tubes,

- - curly wooden plugs for cornices,

- - parchment for baking,

- - cardboard,

- - multi-colored ribbons.

Instructions

Determine the size of the unfolded scroll, cut out a sheet of parchment and outline it.

Glue one edge of the parchment to the cardboard tube, then reinforce the edge by gluing a piece of cardboard to it from the back. Wrap the finished parchment on scroll and tie with a ribbon with a wax seal. Insert the cornice plugs into the side holes of the cardboard tubes and fix them with glue.

By creating scroll, take into account its total size, which includes the additional length of wooden curly plugs glued on both sides. Line the parchment according to your measurements.

To keep the plugs even tighter, choose cardboard tubes in which the plugs you choose will hold tightly and forcefully insert.

Additionally decorate scroll leather and metal fragments, and to complete the magic image, make a magic book out of aged paper.

Fans of nightclubs and discos could not imagine a party without the flashing of all kinds of light lamps, special devices, flickering bright lights and flashes. But to feel the club atmosphere is real at home. And it's not even about expensive lighting installations, although if you have the means, why not create your own impromptu club at home ?!

Instructions

So, for homemade light music, not so much is required, first of all, your right hands and a creative nature! Start with the elementary. Mirror ball. Surely, everyone has CDs at home, most of which have become unusable. They are exactly what you need. First, cut your CDs into 1cm by 1cm squares.

Sometimes you can appearance judge the quality mattress... Particular attention should always be paid to the presence of a removable cover. The fact is that almost all large companies have long abandoned case designs. They are extremely inconvenient to use. In addition, the cover quickly loses its original appearance. Large European companies are engaged in the production of one-piece mattresses and only for stretch fabric mattresses use covers with zippers.

You need to be very careful about the choice mattress for kids . The fact is that the growing body of the child needs the correct positioning of the spine during rest. For each child, you need to select a mattress individually. The best are mattresses with cotton upholstery. Only environmentally friendly materials, such as natural latex, seaweed, coconut plate, should be used as a filler.

Related Videos

Many people dream that their car is environmentally friendly and economical. After all, the waste on gasoline is more and more every day. This article will briefly talk about how to make electric car.

Instructions

Invite your friends and acquaintances to help you create an electric car: engineers, mechanics, electricians, painters. If you have sufficient knowledge in all of these areas, you can do it yourself, but it will take more time and effort.

Remove the combustion engine and everything related to it: the exhaust and fuel systems from the vehicle.

Install the electric motor and gearbox. Connect them to each other. Make the engine mounts to the car body and the battery platform. Install the batteries in the back of the car and connect them together. Make the wiring for the devices, connect the voltmeter.

Install and connect the vacuum pump with switch, DC converter, battery charger, control box, emergency brake. Connect the tubes of the electric pump. Route the power cables under the underbody of the vehicle. To do this, you will need to make several staples on the bottom.

Make a tray for the batteries that will be in front of the car. To do this, you will need to clean and paint the metal. Install the batteries into the body. Complete all connections, add oil to the transmission.

Now you need to check the performance of all devices. Check with the ignition on that the 12 volt appliances are working. Then plug in the 96-volt power supply. Check how the vacuum pump on the brake system works. Check DC / DC converter. Adjust the pump switch settings so that the brakes work properly. Then connect the converter to a 12-volt power supply. Next, start and check the performance of the motor. Everything works - it means electric car turned out.

You will need

- - fluorescent lamps (4 pcs.) of any color;

- - protection for lamps;

- - inventory (can be connected to the cigarette lighter or directly to the battery);

- - wire for connecting the inverter to the battery;

- - chips for T5 and T4 lamps;

- - insulating tape;

- - bolts with nuts;

- - knife, pliers, gloves.

Instructions

Wrap the edges of the lamps with electrical tape, leaving the exposed wires free. Cover everything on top with sealant, which will prevent water, snow from entering.

Install the clamps onto the wires for ease of lamp replacement. You can, of course, just twist the wires and wrap them with electrical tape, but this will not be practical.

If the color is not bright enough or of a different shade, then you can take the tape of the color you need and glue the hose. Repeat all operations for the remaining lamps.

Installing the converter. Route the battery cable through the hole in the glove compartment, and the wires from the ignition blocks to the desired location for installing the lamps.

Route the lamps all the way. Drill the holes for the corners, then bolt them.

Install the lamps on the corners: rear, side, behind the grille and in the engine compartment.

Connect the wires of the ignition units and connect to the inverter.

Neon the backlight is ready.

Related Videos

Seal the surface carefully, slowly, to create a good seal.

As a protection for the lamps, you can use any transparent plastic tube that will protect them in any weather from dirt and snow.

When installing neon lights on the bottom of a particular car, take into account such factors as the condition of the roads in the settlement where the car is operated, the climate of the region, the work of road services (for example, salt sprinkled by the municipality on the roads negatively affects the state of the neon lights of the car), as well as the design features of a particular vehicle.

No matter how long I searched, I never found a master class on the Internet that would tell in detail and step by step about making an orthopedic mattress with my own hands. Therefore, my husband and I decided to do everything at their own discretion, having previously consulted with several friends who sell either furniture or furniture fittings. The result is a very comfortable mattress. And, besides, much cheaper than in the store.

What you need to make a 190x80 cm mattress:

Bonnel springs (size 182x76cm, height 11cm);

Foam rubber 30mm thick, density 28;

- pressed dense felt;

- batting;

- fabric for the mattress;

- roulette;

- marker;

- two-meter flat rail;

- segment knife;

- tailor's scissors;

- glue for foam rubber;

- 6 m of braid;

- zipper closure 1.3 m long.

Visit a store selling furniture accessories (fabrics, sliding mechanisms, etc.). Purchase a mattress spring (bonnel) of the right size, foam rubber, pressed felt, batting, mattress fabric, tape and foam glue.

Note: Most likely, the foam is sold in pre-made sheets of a certain size, so see which size is more appropriate. Felt, batting and mattress fabric are cut materials with a certain standard width. Also calculate the required amount, taking into account not only the width and length of the mattress, but also its height.

We make an orthopedic mattress with our own hands

Step 1. Preparation of parts

Arm yourself with tailor's scissors, a meter or tape measure, a two meter long straight bar, a marker and a segment knife. Measure the required lengths, outline the contours of the parts with a marker and ... Cut the foam with a segment knife using a long strip. Do not forget to put old magazines or plywood under the foam rubber in the places of the cut so as not to scratch the floor or other "working" surface.

Cut the fabric, batting and felt with tailor's scissors.

For a 190x80cm mattress, you will need the following material cuts with these dimensions.

Foam rubber 30 mm thick:

- two pieces 80x190cm;

- two pieces 12x80cm;

- two pieces 12x182cm.

Pressed felt:

- two pieces 76x182cm.

Batting:

- two pieces 195x85cm.

Mattress fabric:

- two pieces 195x85cm;

- two pieces 85x20cm;

-two pieces 195x20cm.

Step 2. Assembling and gluing mattress parts

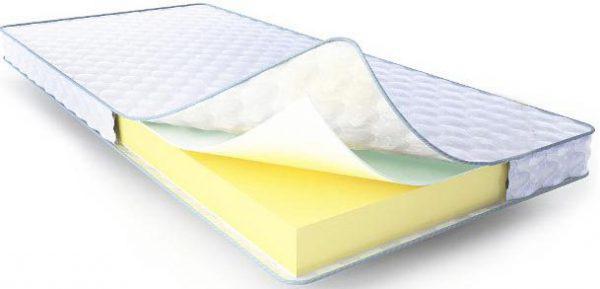

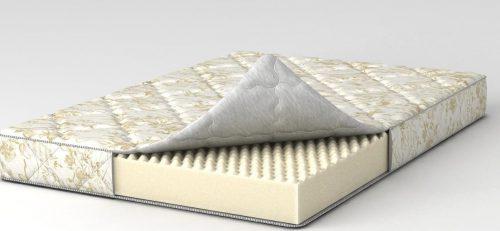

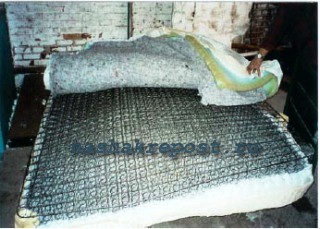

Inside, the mattress should look like the photo below.

So, put a piece of foam rubber (190x80cm) on the floor. Place a piece of pressed felt (182x76cm) on it. Center. Place the springs on the pressed felt.

Glue the short foam side pieces (12x80cm). In this case, foam glue was used. It is not recommended to glue the foam rubber with liquid nails or PVA, because after they dry, a hard crust forms, which is unpleasant to the touch. In addition, PVA dries for a very long time!

A small load can be placed on the part to be glued (several books on a long rail).

After the short side pieces have dried, cover the spring block with the last piece of pressed felt.

Place foam rubber (190x80cm) on top. Glue the top edges of the short side pieces (12x80cm) to the upper foam. Press down with a weight to dry.

The long side pieces can now be glued. To do this, insert them into place, between the upper and lower piece of foam rubber (190x80cm).

Pushing the foam rubber in the right places, apply glue to the side parts and surfaces to be glued to them. Press the weight down on the mattress, and also attach something to the short sides of the mattress to press the side edges of the parts (182x12cm) against the parts (80x12cm).

Note: If you purchase a special foam glue, you can make it easier to bond long sections (like these) as follows. Take a non-bendable piece of wire about 5 mm in diameter. Dip one end of it into a jar of glue and, sticking it in, stretch it between the slightly open surfaces to be glued.

After the glue has completely dried, the mattress is ready for use. It remains to sew a cover for him.

Step 3. Sewing a mattress cover

The first step is to sew the batting to the larger details of the cover.

Note: To prevent the batting from stretching while sewing, you can substitute sheets of unnecessary newspapers under it (you will tear them off later).

Make one more longitudinal seam (in the middle between the long edge of the part and its center seam), securing the cover part and the batting more securely.

Topstitch the side edges of the large cover piece.

Sew the side seam of the cover.

Sew together the four side pieces of the cover along the short edges. You should get a long ribbon sewn into a ring. Make sure that the parts to be stitched are right-side up.

After these procedures, you should get the next set.

Sew one side of the zipper to the piece of tape (85x20cm) that will be sewn to the short edge of the piece (195x85cm). The lock should extend beyond this piece by 22.5 cm in each direction.

Sew together around the perimeter of one large section of the cover and the side sections (in the form of a ribbon). Close the seam with tape.

... Grasp its unsewn long part with a tape and start sewing, grabbing the long edge of the large part by 22.5 cm, then the entire short edge and part of the next long edge (22.5 cm).

The first large part of the cover is sewn on!

Now another one.

A few more efforts: push the mattress into the cover, close the zipper and ... Voila! Orthopedic mattress do it yourself ready!

For many consumers, the discovery will be the fact that foam rubber and polyurethane foam are one and the same! The correct material name is soft polyurethane foam (PPU). Several decades ago, it was supplied to the Soviet Union by the Norwegian company Porolon, so the name has become a household name.

Typical filler requirements:

- Elasticity and firmness.

- Restoring shape after exertion.

Hence the often skeptical attitude towards foam rubber products: they are short-lived, quickly "sag", old foam rubber crumbles. Its main disadvantage is considered to be flammability, poisonous gas is released during combustion.

The quality characteristics of the material changed at the end of the 20th century, when various additives were added to the composition, which influenced the density, elasticity, flammability, etc. Now PUF is used in the manufacture of the vast majority of mattresses.

They use the material in a variety of areas, select for different needs according to certain characteristics. For mattresses, the density of foam rubber is important, the service life of the product depends on it. Use PU foam with a density of 25 to 40 kg / m 3. The density is indicated by two numbers after two letters in the name, the next two numbers indicate the stiffness index.

Mattresses are made from the following brands of foam rubber:

Harm of foam mattresses

If there is a skirting around the perimeter of the bed, measure its height; the mattress should be at least a couple of centimeters higher!

Kinds

Foam mattresses are divided into types depending on the degree of hardness of the products:

Highly elastic elastic foam rubber is used for the mattress. It is also called artificial latex or latex foam rubber.

How to do it yourself?

Everybody periodically needs a new mattress. And many can manage to do it themselves. This may be an option for a summer residence. And it happens that the fabric on the mattress is still good, but the foam has already "sagged".

You will need:

- Foam rubber.

- Mattress cover fabric.

- Felt.

- Foam glue.

If the spring blocks are in good condition, then it is enough to replace only the pieces of foam rubber with new parts.

Algorithm of work:

- Spread the foam rubber on the floor, cover it with felt.

- Glue pieces of foam rubber on the sides to hide the springs.

- On top, when the glue dries, put felt, and then foam rubber.

- The final step is to insert the foam rubber into the cover.

If you need a new mattress without springs, you first need to decide on its size. Purchase foam rubber of the required parameters. Then sew the mattress topper. Consider seam allowances when cutting. All that remains is to place the PUF in the case.

On the video do-it-yourself foam mattress:

Manufacturers, product cost

Attention! When choosing a mattress, carefully study the reviews on the forums!

It is quite possible to choose a foam mattress good qualitywhich will last up to five years without “sagging”. And models with a higher density remain suitable for operation for 10 years. And one more benefit of the products is the affordable price. Weigh the pros and cons, and then choose! You may also be interested in. You can choose . Maybe you need an orthopedic mattress cover. Very comfortable.

None of us can imagine how one can indulge in sleep and rest on bare ground or on a hard wooden bed. Modern man accustomed to the fact that his body should recline on a soft basis of one kind or another.

Most of the time, we sleep on a mattress. Today we will reveal the secret of how you can make a mattress using various natural or artificial materials with your own hands.

If even in the last century the basis of this product was mainly made up of various fillers of plant or animal origin, then in modern mattress the main component is a spring. It is she who provides comfort and convenience.

There are so many types of this wire element you can not find in modern beds. Each manufacturer constantly strives to prove that it is his development that most fully takes into account the peculiarities of human forms and allows the body to take the most favorable position in terms of rest.

And there are more and more enterprises producing these products for the modern market. The most responsible of them really spend a lot of money on studying the peculiarities of the operation of springs of various forms, select their optimal ratio per unit area, experiment with various artificial and natural fillers.

Making a mattress using natural materials

At the same time, one of the main negative aspects associated with limiting the consumption of new generation mattresses is their rather high price. We bring to your attention a budget version of the product, which can be made by hand for a private house or summer cottage, using both traditional and not quite traditional, or materials forgotten over time.

We start the process of making a mattress with a fabric base - a cover of a certain size, which we will fill in the future. A sufficiently strong fabric must be prepared for sewing the casing. Moreover, it can be both traditional white, and any other, since the operation of the mattress is often carried out using bed linen.

From the prepared fabric, make a pattern for the details of the future homemade product. It will consist of two completely identical rectangular parts, the dimensions of which will depend both on the size of the people who will use the product and on the type of bed. Recall that modern stocks are divided in width into single, one and a half and double. Based on this, cut out the upper and lower half of the mattress. In addition to them, prepare one or more narrow strips, the width of which will determine the height of the product, and the total length should not be less than the perimeter (the sum of the lengths of the sides) of rectangular parts.

The cut parts must be connected together. To do this, first grind them with pins,

sweep and sew with high strength threads. It is best to first perform this operation manually, securely fixing the parts to each other in order to avoid their mutual displacement.

This is necessary to achieve high quality work. A strong thread will help to achieve maximum wear resistance of the joints of the fabric and the entire product as a whole. Of the most commonly used, it is possible to recommend using a linen seam for these purposes.

Don't try to put all the pieces together. Remember to leave one short side unstitched. You will need it to fill the mattress. It is best to make a neckline in this part, which can be locked with a zipper or buttons.

Traditionally, the mattress assumes the most lush shape possible. To achieve this goal, a large list of different materials can be recommended for use. Remembering the fairy tale about the princess and the pea, try filling our product with down or feather. Considering its required quantity and the price of such materials, the cost of such a product will many times exceed the cost of the most expensive factory product. Instead of poultry products, you can use another natural material - livestock product - sheep wool... It is also capable of retaining volume and has very high heat-retaining properties. Such a product can be made only for the cold winter period and in the presence of a sufficient amount of wool.

We suggest paying attention to one, perhaps the cheapest, but not the worst material for stuffing a homemade mattress - hay. It is a quality dried young herbs with an unforgettable natural aroma. And if you add 5-10% of dried mint, hop cones and other soothing plants to its composition, sleeping on such a product will bring you an unforgettable rest.

The choice of filler for the mattress

For stuffing the cover, we recommend using a large piece of clean plastic wrap, on which we lay the future mattress and gradually tamp the dried herbs into it. Using straw or mature grass for these purposes is not advisable, as tough stems can ruin the whole experience of rest.

It is better to carry out work on padding the mattress in work gloves and clothes with long, buttoned sleeves. Otherwise, small scratches, many of which appeared on your hands, cannot be avoided.

If there are agricultural processing enterprises in the immediate vicinity of your location, you can fill the mattress with, for example, buckwheat husks or other similar material.

Instead natural filler you can also use the products of chemical production in the form of a recently appeared substitute for wool - synthetic winterizer. It is lightweight, soft and non-allergenic.

After completing the above steps, you will become the owner of a unique product that will give you an unforgettable vacation and arouse the interest of your friends and acquaintances.

Dear readers, comment on the article, ask questions, subscribe to new publications - we are interested in your opinion :)

New articles

- Sasaki sadako paper cranes

- How to draw a hummingbird with a pencil step by step How to draw a hummingbird with a pencil step by step

- How to draw a colorful illustration in Photoshop

- Pencil drawing lessons

- Step by step instructions on how to draw a teddy bear How to draw a teddy bear with a pencil

- Draw realistic hummingbirds Draw hummingbirds with a pencil

- Unusual drawing techniques for children

- Types and techniques of non-traditional drawing

- How to draw a beautiful tree step by step

- How to draw an autumn tree

Popular articles

- Master class of a beautiful landscape with step by step photos How to draw an autumn tree correctly

- Unconventional winter tree drawing techniques Tree branch winter drawing

- The funniest children's jokes

- Technique of drawing with crumpled paper in kindergarten, school: master class

- Non-traditional drawing techniques for children in kindergarten and school How to draw with crumpled paper

- Draw animals by cells in a notebook

- How to draw a sailboat with a pencil step by step

- Virtual tours of the best museums

- How to draw a New Year's gift on a graphics tablet?

- “He was my classmate